BALL STUDS AND BALL-AND-SOCKET CLAMPS FOR TEMPORARY GROUNDING

| Ball Studs | Ball-And-Shell |

| ATR08969-3 | RC600-2300 |

| ATR13147-1 | RT600-2321 |

Pino-Bola para Ponto de Aterramento Temporário

The ball stud and ball-and-socket clamp are designed to solve countless temporary grounding situations where space or contact surfaces are limited.

In switchgears, especially with rectangular buses, where conventional ground clamps have dimensions that preven their use, the ball-and socket clamp stands out for its versatile design and easy operation.

This clamp is very popular in electrical installations such as:

- switchgears;

- indoor and outdoor substations;

- overhead cranes;

- hot line vehicles;

- painted transmission line structures where optimum electrical contact with conventional clamps is not obtained.

Ball studs are designed for permanent installations in buses, bus junctions, terminals or other parts of the electrical installation, establishing the points necessary for their proper temporary grounding. Therefore, purchasing them in sufficient quantities for such use is recommended.

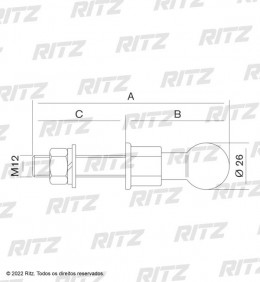

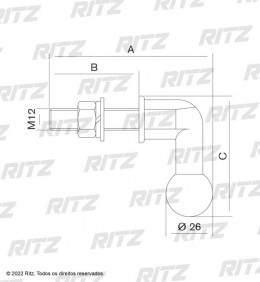

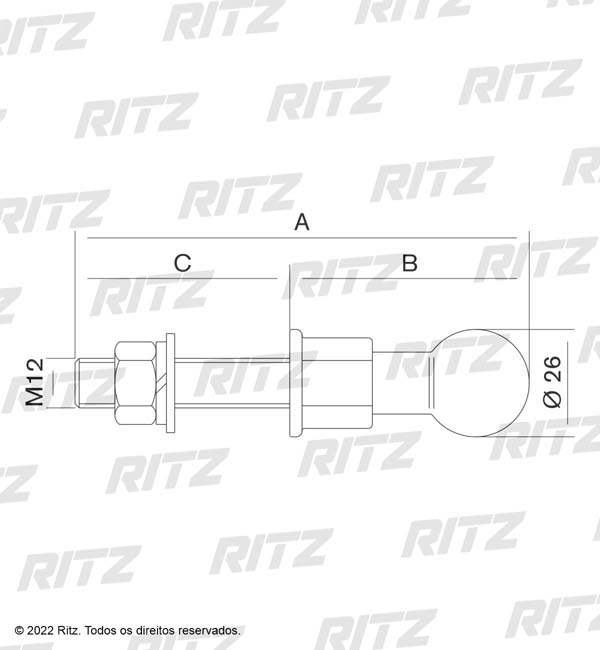

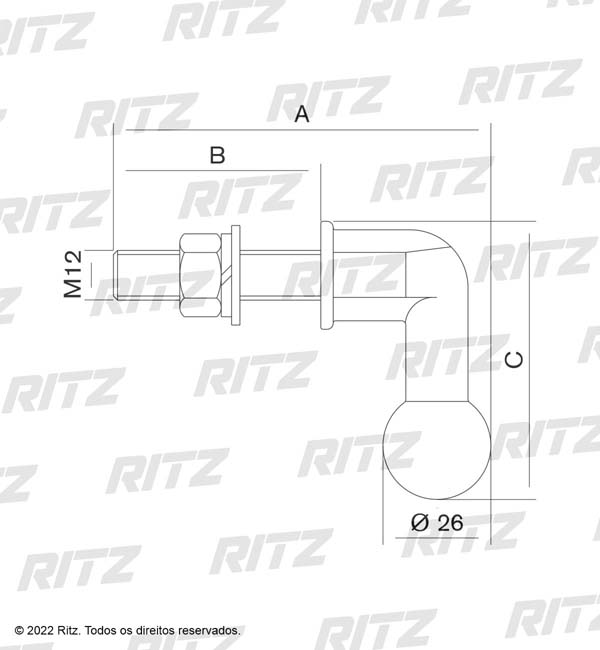

To best suit the user needs, they are arranged with seven variations in connecting ball length and position.

Bronze alloy body and tin-plated 1020 steel thread and 3.5 daN.m installation torque.

| Catalog Reference | A | B | C | Approx. Weight | |

| kg | LB | ||||

| ATR08969-1 | 98 | 58 | 40 | 0,22 | 0,48 |

| ATR08969-2 | 118 | 58 | 60 | 0,24 | 0,53 |

| ATR08969-3 | 138 | 58 | 80 | 0,25 | 0,55 |

| ATR08969-4 | 108 | 58 | 50 | 0,23 | 0,51 |

| ATR08969-5 | 166 | 114 | 52 | 0,28 | 0,62 |

| ATR08969-6 | 158 | 58 | 100 | 0,30 | 0,66 |

| ATR08969-7 | 82 | 58 | 100 | 0,28 | 0,62 |

19070

| Catalog Reference | A | B | C | Approx. Weight (kg) | |

| ATR13147-1 | 91 | 50 | 65 | 0526 | 0.57 |

24258

GROUND CLAMPS

|  |  |  |  | ||

| Electrical and Mechanical Characteristics | Catalog Reference | |||||

| RC600-2300 | RT600-2321 | RC600-2101 | ATR08968-1 | RT600-2320 | ||

| Description | Bronze alloy main body; Eyescrew; Cable connection through plain ferrule | Bronze alloy main body; T-handle; Cable connection through plain ferrule | Bronze alloy main body; Eyescrew; Cable connection through threaded ferrule | Bronze alloy main body; Eyescrew; Cable connection through tin-plated copper ferrule | Bronze alloy main body; T-handle; Cable connection through threaded ferrule | |

| Rated Current (A) | 400 | 400 | 400 | 400 | 400 | |

| Short circuit current (lcc) | 30 cycles (kA) | 30 | 30 | 30 | 30 | 30 |

| 60 cycles (kA) | 23 | 23 | 23 | 23 | 23 | |

| Connection | Ø 26 | Ø 26 | Ø 26 | Ø 26 | Ø 26 | |

| Cable Ferrule (mm²) | Maximum | 95 | 95 | 95 | 95 | 95 |

| Minimum | 25 | 25 | 25 | 25 | 25 | |

| Installation Torque (daN.m) | 3,0 | 3,0 | 3,0 | 3,0 | 3,0 | |

| ASTM Designation | Type I Class A Grade 5 | Type III Class A Grade 5 | Type I Class A Grade 5 | Type I Class A Grade 5 | Type III Class A Grade 5 | |

| Approx. Weight. (kg / lb) | 0,76 | 0,82 | 0,45 | 0,40 | 0,45 | |

711-3411 ; 711-3432